Fused Deposition Modeling (FDM) 3D printing has revolutionized prototyping, manufacturing, and hobbyist creation. For years, the conversation around 3d printing filament primarily revolved around a few key players. But the landscape is rapidly evolving. While the trusty workhorses remain essential, a new generation of innovative materials is pushing the boundaries of what’s possible with desktop and industrial FDM machines. These advanced filaments offer unique properties, opening doors to applications previously thought impossible for extrusion-based printing.

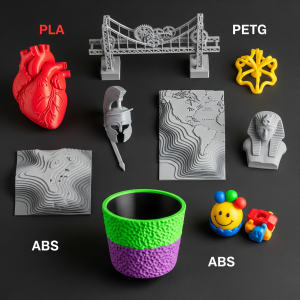

If you’re involved in FDM printing, you’re likely familiar with the standard trio: PLA, ABS, and PETG. Let’s quickly recap why they’re popular before diving into the exciting innovations.

The Workhorses: A Quick Refresher

- PLA Filament (Polylactic Acid): Often the first filament beginners encounter, PLA filament is beloved for its ease of use. It prints at relatively low temperatures, doesn’t require a heated bed (though it helps), exhibits minimal warping, and comes in a vast array of colors. Derived from renewable resources like corn starch, it’s more environmentally friendly than petroleum-based plastics, being biodegradable under specific industrial composting conditions. Its main drawback is its relative brittleness and lower temperature resistance compared to other materials. Ideal for visual prototypes, artistic models, and low-stress applications.

- ABS Filament (Acrylonitrile Butadiene Styrene): Known for its strength, durability, and higher temperature resistance, ABS filament is the same type of plastic used in LEGO bricks. It can be sanded easily and smoothed with acetone vapor for a glossy finish. However, it requires higher printing temperatures, a heated bed (often an enclosure) to prevent warping and cracking, and emits potentially irritating fumes during printing. A solid choice for functional parts that need toughness.

- PETG Filament (Polyethylene Terephthalate Glycol): Offering a good middle ground, PETG filament combines much of PLA’s ease of printing with ABS-like strength and durability. It has excellent layer adhesion, low warping, and good chemical resistance. Many PETG filaments are considered food-safe (always check manufacturer specifications). It can be prone to stringing and absorbs moisture (hygroscopic), so proper storage is key. Great for mechanical parts, containers, and functional prints requiring more resilience than PLA.

These materials cover a lot of ground, but what if you need more? What if you need metal-like strength, extreme flexibility, conductivity, or true biodegradability? That’s where material science innovation shines.

Enter the Superpolymers: The Case of Tullomer

One of the most striking examples of next-generation 3d printing filament is Tullomer, developed by Z-Polymers. Billed as a potential replacement for metals like aluminum and steel, as well as high-performance polymers like PEEK and ULTEM, Tullomer represents a significant leap. Its innovation lies in its molecular structure – it’s a 100% crystalline polymer with “Mesogen Nematic Structures” that align during printing, creating fiber-like properties without actual fibers.

Key features include:

- Exceptional Strength-to-Weight: Reportedly stronger and significantly lighter than steel.

- High Stiffness and Dimensional Stability: Maintains precise dimensions, crucial for engineering applications.

- Thermal Resistance: Stable up to around 200°C.

- Chemical Resistance & Low Moisture Absorption: Durable in harsh environments.

- No Annealing Required: Simplifies post-processing compared to some high-performance materials.

- Flame Retardant: Meets UL94 V-0 standards.

While Tullomer demands high printing temperatures (300°C+ nozzle, 110°C+ bed, often a heated chamber) and careful tuning (especially for Z-axis adhesion), it demonstrates the incredible potential of advanced polymer science in FDM printing, pushing into territory previously dominated by traditional manufacturing or more complex printing technologies. It’s a glimpse into a future where FDM printers can produce parts with truly exceptional mechanical properties.

Strength and Structure: Composite Filaments

Beyond single-polymer innovations, composite filament options blend base plastics (often PLA, PETG, or Nylon) with other materials to enhance properties:

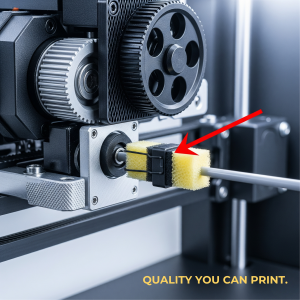

- Carbon Fiber Filled: Adding short, chopped carbon fibers significantly increases stiffness, strength, and dimensional stability without drastically increasing weight. PLA-CF, PETG-CF, and Nylon-CF are popular choices for printing strong, rigid functional parts like drone frames, jigs, fixtures, and tooling. Be aware: carbon fiber is abrasive and requires a hardened steel nozzle to prevent rapid wear.

- Wood Filled: These filaments mix PLA with fine wood powder or fibers (like bamboo, cork, or pine). They produce parts with a unique, wood-like appearance and texture, often even smelling like wood during printing. Great for aesthetic prints, models, and decorative items. They can be slightly more brittle than standard PLA and may require larger nozzle sizes (e.g., 0.5mm or 0.6mm) to prevent clogging.

- Metal Filled: Containing a high percentage of fine metal powder (bronze, copper, brass, stainless steel, iron) suspended in a polymer binder (usually PLA), these filaments create parts that are significantly heavier than standard plastic prints and have a metallic look. They can often be post-processed (sanded, polished, tumbled, even patinated or rusted for iron-fill) to achieve a realistic metal finish. Like carbon fiber, they are highly abrasive and demand hardened nozzles.

Getting Flexible: TPUs and TPEs

For applications requiring elasticity and impact resistance, flexible filament like TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer) are the answer. TPC (Thermoplastic Copolyester) is another variant. These materials allow you to print objects that can bend, stretch, and absorb shock.

- TPU: Generally the easiest flexible filament to print with, offering a good balance of flexibility and printability. It’s available in various hardness levels (Shore hardness).

- TPE: Often softer and more ‘rubbery’ than TPU, but can be more challenging to print, requiring slower speeds and well-calibrated extruders (direct drive systems usually perform better).

Flexible filaments are perfect for creating phone cases, grips, seals, gaskets, vibration dampeners, and even custom shoe soles.

Special Effects and Aesthetics

Innovation isn’t just about performance; it’s also about visual appeal:

- Glow-in-the-Dark: PLA infused with phosphorescent additives that charge under light and glow in the dark. Fun for toys and decorations, but the additives can be abrasive (consider a hardened nozzle).

- Color Changing: Includes thermochromic filaments (change color with temperature) and UV-reactive filaments (change color when exposed to sunlight/UV). Great for visual indicators, novelty items, or just adding a ‘wow’ factor.

- Silk/Rainbow/Multi-Color: “Silk” PLA filaments contain additives that give prints a distinct glossy, smooth, almost metallic sheen that reflects light beautifully, often hiding layer lines. Rainbow filaments transition through multiple colors on a single spool, creating gradient effects on larger prints. Dual and Tri-color filaments have multiple distinct color strands extruded together, creating prints that shift color depending on the viewing angle.

Pushing Boundaries: High-Temperature & Specialized Filaments

Beyond Tullomer, other high-performance materials cater to demanding applications:

- PC (Polycarbonate): Extremely strong, tough, and heat resistant. Often used for functional prototypes and end-use parts requiring high impact resistance. It requires very high printing temperatures and is very prone to warping and moisture absorption.

- PEEK/PEKK/ULTEM: These are ultra-performance thermoplastics offering exceptional heat resistance, chemical inertness, and mechanical strength. They require specialized industrial printers capable of very high nozzle (400°C+) and chamber temperatures.

- Conductive Filament: By incorporating conductive materials like carbon black or graphene, these filaments allow for printing simple electronic circuits, capacitive sensors, or parts for EMI/RFI shielding directly within a plastic structure. Conductivity is typically much lower than actual wires but sufficient for specific low-power applications.

The Greener Path: Sustainable Innovations

As environmental awareness grows, so does the demand for sustainable 3d printing filament:

- PHA (Polyhydroxyalkanoate): This biopolymer is produced by microorganisms and is marketed as being truly biodegradable under various conditions (including home compost and marine environments), breaking down without leaving harmful microplastics. While availability has fluctuated (Beyond Plastic, a key supplier, paused filament production), PHA represents a promising, more broadly biodegradable alternative to PLA.

- Recycled Filaments (rPLA, rPETG, etc.): Made from post-industrial or post-consumer plastic waste, these filaments help close the loop, reducing landfill burden and conserving resources. Quality can match virgin materials, offering a direct sustainable swap.

- Bio-Based Composites: Filaments like Bamboo Fill PLA incorporate fast-growing, renewable plant matter, reducing the reliance on plastics.

Final Thoughts: Embrace the Material Possibilities

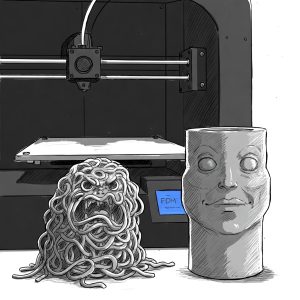

The world of 3d printing filament is far more diverse and exciting than ever before. While PLA filament, ABS, and PETG remain foundational, the emergence of innovative materials like Tullomer, advanced composites, versatile flexibles, and sustainable options drastically expands the application range of FDM printing.

Understanding these materials and their unique properties is key. Keep in mind that many advanced filaments require specific printer capabilities (like all-metal hotends, hardened nozzles, heated chambers) and careful tuning of print settings. But for those willing to experiment, the potential to create stronger, lighter, more flexible, more functional, or more sustainable parts is immense. So, look beyond the basics and explore the cutting edge – your next project might just depend on it!