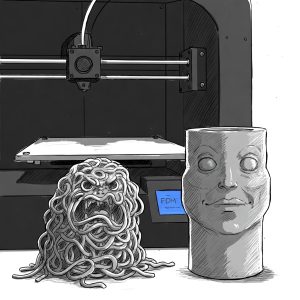

You’ve been there. Hours into a complex print, everything seems to be going smoothly. You step away, dreaming of the perfect model you’ll soon hold, only to return to a bird’s nest of tangled plastic, a nozzle hopelessly clogged, or a print so flawed it’s destined for the bin. The frustration is palpable. You check your settings, level the bed again, maybe even question your sanity. But what if the culprit is something far more insidious, something you might not even see? What if the very lifeblood of your printer – your 3d printing filament – is silently sabotaging your efforts and your wallet?

It’s a common oversight. We meticulously calibrate our machines, debate the merits of different slicer settings, and invest in the latest printer upgrades. Yet, the humble spool of 3d printing filament often doesn’t get the careful attention it deserves before it enters the extruder. This article will pull back the curtain on the unseen enemies lurking on your filament and explore how prioritising clean 3d printing filament is not just a minor detail, but a cornerstone of successful, reliable, and cost-effective 3D printing. Prepare to discover how a little preventative care can save you a significant amount in time, materials, and replacement parts.

What Exactly Makes “3D Printing Filament” Dirty? The Line-Up of Culprits

Before we can combat the enemy, we need to understand its forms. “Dirty” 3d printing filament isn’t just about visible clumps of grime; it encompasses a range of contaminants that can wreak havoc on your printing process.

- Dust and Airborne Particulates: This is the most common offender. Your workshop, garage, or even a seemingly clean room is teeming with microscopic dust particles, pet dander, lint, and other airborne debris. When a spool of 3d printing filament sits exposed, it acts like a magnet for these particles. Even a thin, almost invisible layer of dust can accumulate over time, ready to be dragged directly into your printer’s hotend.

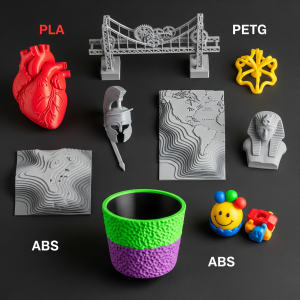

- Moisture Absorption (Hygroscopy): Many popular types of 3d printing filament, including PLA, ABS, PETG, Nylon, and TPU, are hygroscopic. This means they readily absorb moisture from the ambient air. Humid environments, like many parts of Australia, can be particularly challenging. Wet filament doesn’t just lead to poor print quality (think sizzling, popping, bubbles, and brittle prints); the steam generated can also contribute to nozzle blockages and inconsistencies.

- Oils and Residues: Handling your 3d printing filament with oily or greasy hands can transfer these residues onto the strand. While seemingly minor, these oils can carbonize in the hotend, contributing to build-up and eventual clogs. Sometimes, lower-quality 3d printing filament might even carry residual manufacturing lubricants or coatings that can cause similar issues.

- Improper Storage: This ties all the above points together. Leaving spools of 3d printing filament out in the open, unprotected from dust and humidity, is an open invitation for contamination. Even the plastic bag your filament arrived in isn’t sufficient once opened if not resealed properly with desiccant.

Understanding these sources is the first step towards protecting your 3d printing filament and, by extension, your 3D printer.

The Cascade of Problems: How Contaminated “3D Printing Filament” Derails Your Prints and Damages Your Printer

The journey of a contaminated piece of 3d printing filament from the spool to the nozzle tip is fraught with peril – not for the filament, but for your printer and your print. The problems aren’t isolated; they create a domino effect that can escalate from minor annoyance to major mechanical failure.

- Nozzle Nightmares: The Primary Victim

Your printer’s nozzle is a precision-engineered component with a tiny orifice, often ranging from 0.2mm to 0.8mm. It doesn’t take much to cause a problem here.

- Mechanism of a Clog: Dust particles, even microscopic ones, can accumulate at the nozzle opening. When the 3d printing filament melts, these particles don’t. They can get caught, creating a partial blockage that restricts flow. If enough debris gathers, or if moisture in the filament turns to steam and causes rapid, uneven cooling of the molten plastic, a full clog can occur. This brings your print to an abrupt halt and often requires a frustrating and time-consuming cleaning process, or even nozzle replacement.

- Abrasive Action – The Sandpaper Effect: Think of hard dust particles or debris embedded in your 3d printing filament as tiny grains of sandpaper. As the filament is forced through the nozzle, these particles grind against the inner walls. Brass nozzles, common due to their excellent thermal conductivity, are particularly susceptible to this wear. Over time, this abrasive action will widen the nozzle orifice. A nozzle that started at 0.4mm might become 0.45mm or 0.5mm. This seemingly small change has a huge impact on extrusion accuracy, line width, and overall print quality, leading to over-extrusion and loss of fine detail. You’ll find yourself constantly recalibrating, unaware that your nozzle is slowly being destroyed.

- Reduced Nozzle Lifespan & Increased Costs: The direct consequence of frequent clogs and abrasion is a drastically reduced nozzle lifespan. What might have lasted for hundreds of printing hours could be rendered useless in a fraction of that time if you’re consistently feeding it dirty 3d printing filament. While a single brass nozzle isn’t a huge expense, the costs add up quickly, especially if you’re running multiple printers or a print farm. Add to this the cost of failed prints and wasted 3d printing filament, and the financial impact becomes significant.

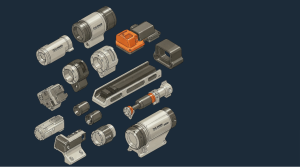

- Extruder and Hotend Strain: Beyond the Nozzle

The damage isn’t confined to the nozzle. The entire extrusion system can suffer.

- Increased Friction and Extruder Gear Wear: Dust and debris on the 3d printing filament increase friction as it passes through the extruder gears. These gears bite into the filament to push it towards the hotend. If the filament is coated in grit, these gears can become caked with debris or even wear down prematurely, losing their ability to grip the filament effectively. This can lead to filament grinding (where the gears chew up the filament instead of pushing it) and under-extrusion.

- Heat Creep and Hotend Build-up: Partial clogs caused by dirty 3d printing filament can lead to increased pressure within the hotend. This can cause heat to “creep” upwards from the heater block into the heat break (the cool zone of the hotend). When the 3d printing filament melts too early in its path, it expands and can cause a more stubborn jam that’s harder to clear. Furthermore, contaminants can cook and carbonize inside the hotend assembly, leading to persistent flow issues.

- Print Quality Degradation: The Visible Disasters

Ultimately, the most visible impact of dirty 3d printing filament is on your finished prints.

- Artifacts, Blemishes, and Zits: Specks of dust or debris embedded in the filament often get deposited onto or into your print, creating unsightly zits, blobs, or discoloured spots on the surface.

- Inconsistent Extrusion: Partial clogs or worn nozzles lead to inconsistent flow rates. This manifests as visible lines in your print, sections of under-extrusion (gaps, weak layers) or over-extrusion (blobs, loss of detail).

- Poor Layer Adhesion: Contaminants or moisture on the surface of the 3d printing filament can interfere with how well one layer bonds to the next. This results in structurally weak prints that can easily delaminate or break.

- Brittleness, Sizzling, and Popping: This is a classic sign of wet 3d printing filament. As the moist filament hits the hot nozzle, the water rapidly turns to steam, creating tiny air bubbles within the extruded plastic. This not only weakens the print significantly, making it brittle, but you might also hear audible sizzling or popping sounds during printing – a clear distress signal from your machine.

The message is clear: contaminated 3d printing filament is a pervasive threat that undermines print quality, accelerates wear and tear on your machine, and costs you money.

The Unsung Hero: Tangible Benefits of Using Clean “3D Printing Filament”

Now for the good news! The effort required to maintain clean 3d printing filament is minimal compared to the significant rewards. Prioritising filament hygiene isn’t just about avoiding problems; it’s about unlocking the full potential of your 3D printer and your materials.

- Extended Nozzle Life: This is one of the most immediate and tangible benefits. By feeding your printer clean, pure 3d printing filament, you dramatically reduce abrasive wear and the frequency of clogs. Nozzles last longer, meaning fewer replacements and lower operational costs.

- Enhanced Machine Reliability and Reduced Downtime: Fewer clogs and less strain on the extruder mechanism mean your printer runs more smoothly and reliably. You’ll spend less time troubleshooting frustrating filament jams and more time actually printing. This is crucial for hobbyists who want to enjoy their craft and indispensable for businesses where printer downtime equals lost revenue.

- Superior and Consistent Print Quality: Clean 3d printing filament is the foundation for flawless prints. Expect smoother surfaces, sharper details, better layer adhesion, and more consistent extrusion. Colours will appear truer without specks of debris marring the finish. Your prints will not only look better but will also be stronger and more dimensionally accurate.

- Time and Material Savings: Every failed print due to a clog or poor quality from dirty 3d printing filament means wasted material and wasted time. By ensuring your filament is clean and dry, you significantly increase your print success rate. This means less discarded plastic and fewer hours spent reprinting jobs.

- Peace of Mind: Knowing you’ve taken steps to eliminate a major variable for print failure allows for a more confident and enjoyable printing experience. You can trust your machine and your 3d printing filament to perform as expected.

Investing a little attention in your 3d printing filament pays substantial dividends in the long run.

Practical Strategies: Keeping Your “3D Printing Filament” Pristine from Spool to Nozzle

Convinced? Excellent. Now let’s look at practical, actionable steps you can take to ensure your 3d printing filament stays in prime condition.

- Proper Storage is Non-Negotiable:

- Airtight Containers: Store your spools of 3d printing filament in airtight plastic containers with good seals. Large, resealable bags (like vacuum storage bags) also work well.

- Desiccants are Your Best Friend: Always include desiccant packs (silica gel is common and can often be “recharged” by drying in an oven) inside your storage containers. These will absorb any moisture that gets in or is already present. Replace or recharge them regularly.

- Filament Filters/Cleaners – An Easy Win:

- Before the 3d printing filament enters your extruder, you can pass it through a simple cleaner. This can be a small, 3D-printed clip that holds a piece of sponge or cloth lightly around the filament. The sponge wipes off dust and small particulates. Some people add a tiny drop of mineral oil to the sponge to help trap dust, but use this sparingly as too much oil can cause its own issues.

- Filament Dryers for Rescue and Maintenance:

- For 3d printing filament that has already absorbed moisture, or for particularly hygroscopic materials like Nylon or Polycarbonate, a dedicated filament dryer is an excellent investment. These devices actively heat and circulate air to remove moisture. Some can even be used to feed filament directly to the printer while keeping it dry. In a pinch, some filaments (check manufacturer recommendations carefully!) can be dried in a conventional oven at very low temperatures, but this requires extreme caution and accurate temperature control to avoid melting or damaging the filament or spool.

- Mindful Handling Practices:

- Wash your hands before handling new spools or loading 3d printing filament to avoid transferring oils.

- Minimise the time a spool is left sitting out in the open. If you’re not printing with it, store it.

- Sourcing Quality “3D Printing Filament”:

- While not strictly a cleanliness tip, starting with high-quality 3d printing filament from reputable suppliers like NE3D Printing can make a difference. Good quality filament is more likely to have consistent diameter, be free of manufacturing residues, and come well-packaged to protect it during transit and initial storage.

Conclusion: Clean Filament – A Small Effort for Big Rewards

The journey to flawless 3D prints and a long-lasting, reliable printer has many contributing factors, but the cleanliness of your 3d printing filament is undeniably one of the most crucial yet often underestimated. The hidden enemies of dust, moisture, and residues can silently sabotage your efforts, leading to frustrating failures, damaged components, and unnecessary expenses.

By implementing simple, proactive strategies for storing, handling, and if necessary, cleaning and drying your 3d printing filament, you transform it from a potential liability into a consistent asset. The small investment in time and perhaps a few accessories for filament care will be repaid many times over in improved print quality, extended machine life, reduced waste, and a far more enjoyable and productive 3D printing experience. Don’t let filth kill your flow; make pristine 3d printing filament the standard in your workshop, and watch your printing success soar.