N.E Print Shop

Beyond Chopped Strands: Could We Create Continuous Fiber-Infused 3D Printing Filament Inspired by DIY Innovation?

NE Print Shop

N.E Print Shop

NE Print Shop

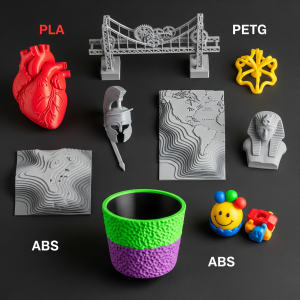

The world of 3d printing filament is constantly evolving. From basic PLAs to exotic composites, manufacturers and hobbyists alike are pushing the boundaries of what’s possible. We’ve seen filaments infused with wood, metal, and, notably, chopped carbon fiber, all designed to enhance the properties of 3D printed parts. These “reinforced” 3d printing filament options offer a step up in strength or aesthetics compared to their pure polymer counterparts. But what if we could take fiber reinforcement a giant leap further, moving from short, dispersed strands to a truly continuous fiber embedded directly within the 3d printing filament itself?

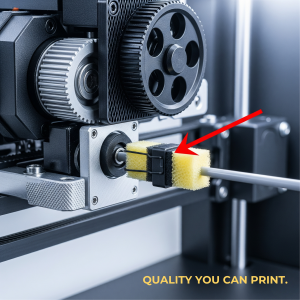

This question isn’t just a flight of fancy. It’s an exciting engineering challenge with the potential to unlock new levels of performance for Fused Filament Fabrication (FFF) 3D printing. Recently, a fascinating YouTube video (referred to as https://www.youtube.com/watch?v=CQ-N1fr4N0w in the user’s prompt, which detailed a process of reshaping 3mm filament to 1.75mm and even creating custom multi-color or multi-material filaments at home using a relatively simple heated nozzle and pulling mechanism) sparked an intriguing thought: could a similar principle be adapted to create a 3d printing filament with a continuous, unbroken fiber core?

The video demonstrated how one could take existing filament – even combining different types or colours – and extrude it through a shaping die to create a new, custom 3d printing filament. The process involved carefully controlling temperature to soften the plastic enough to be pulled and reshaped, without becoming too brittle or molten. The creator even showcased embedding custom shapes and combining materials like a TPU core within a PLA shell. This resourceful approach to filament modification begs the question: could we use such a method to inlay a continuous strand of reinforcing material – like carbon fiber, Kevlar, or fiberglass – directly into a thermoplastic filament as it’s being formed?

The Limitations of Current “Fiber-Filled” 3D Printing Filament

Before diving into the “how,” let’s consider the “why.” Most commercially available fiber-reinforced 3d printing filament options, such as those containing chopped carbon fiber, offer certain benefits like increased stiffness, reduced warping, and improved surface finish. The carbon fibers, typically only a few hundred microns long, are mixed with the base polymer (like PLA, PETG, Nylon, or ABS) before it’s extruded into the 3d printing filament we buy.

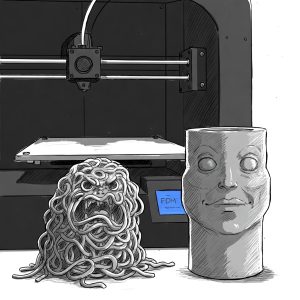

While these chopped fibers do enhance some material properties, their discontinuous nature means they don’t provide the same level of structural reinforcement as a continuous fiber would. Imagine trying to build a strong rope bridge with short pieces of string versus using long, unbroken cables. The load-bearing capacity is vastly different. In chopped fiber filaments, the strength is still largely dependent on the polymer matrix adhering to these small fibers and transferring stress between them. While an improvement, it doesn’t fully leverage the incredible tensile strength that materials like carbon fiber possess along their length. The resulting parts are often stiffer, but not dramatically stronger in terms of tensile or flexural load-bearing capacity compared to what a continuous strand could offer. Furthermore, the random orientation of these short fibers, while sometimes beneficial for isotropic properties, doesn’t allow for strategic reinforcement along specific stress paths in a printed part.

The Allure of Continuous Fiber Reinforcement

Continuous Fiber Reinforcement (CFR) is the gold standard for creating truly high-strength composite parts. In the broader composites industry (think aerospace, automotive racing, high-performance sporting goods), continuous fibers are meticulously laid down in specific orientations within a resin matrix to create components that are exceptionally strong and lightweight.

In the 3D printing realm, companies like Markforged and Anisoprint have pioneered CFR technologies. These systems typically use a specialized print head with two nozzles. One nozzle extrudes a standard thermoplastic 3d printing filament (often Nylon or a tough composite like Onyx, which itself contains chopped carbon fibers) to form the bulk of the part and its outer shell. The second, more sophisticated nozzle, precisely lays down a continuous strand of fiber (carbon, fiberglass, or Kevlar) into the thermoplastic as it’s being printed. This fiber is essentially “ironed” into the still-molten plastic of the current layer.

This approach allows for strategic placement of reinforcement, concentrating strength where it’s most needed – along perimeters, through specific internal structures, or across entire layers. The results are impressive, producing parts with strength properties that can rival machined aluminum, but with significantly less weight. This has opened doors for functional prototyping, custom tooling, jigs, fixtures, and even end-use parts in demanding applications.

However, these dedicated CFR printers represent a significant investment and often require proprietary materials and software. The process of laying down the fiber during printing also adds complexity and can increase print times.

Could We Create a Pre-Made Continuous Fiber 3D Printing Filament?

This brings us back to the initial idea: what if, inspired by the DIY filament reshaping video, we could manufacture a 3d printing filament that already contains a continuous reinforcing fiber within its core? Imagine a standard-looking 1.75mm or 2.85mm spool of 3d printing filament, but with a single, unbroken strand of carbon fiber (or similar) running through its entire length, perfectly co-extruded with a thermoplastic like PETG or Nylon.

The Conceptual Process:

Drawing inspiration from the video’s technique of pulling softened plastic through a shaping nozzle, one could envision a setup where:

This method, in essence, would be a micro-pultrusion or co-extrusion process, creating a ready-to-use 3d printing filament with an integrated continuous structural element.

Potential Advantages of such a “Continuous Core” 3D Printing Filament:

Significant Technical Challenges:

While the concept is tantalizing, producing and using such a 3d printing filament would present numerous technical hurdles:

Comparison to Existing Research and DIY Efforts:

The idea of embedding continuous fibers into a thermoplastic matrix to create a reinforced filament isn’t entirely new in research circles. Studies like the one from PMC involving PET fibers and PLA demonstrate lab-scale processes where continuous fibers are drawn through a melt pool of polymer and then through a die to create a composite filament. These studies often focus on characterizing the properties and exploring the feasibility.

On the DIY front, as seen in some online forums and videos (some mentioned in the Google Search results), adventurous makers have experimented with co-extruding carbon tows with thermoplastics using modified extruders. While these efforts are commendable and demonstrate ingenuity, achieving consistent quality, good impregnation, and reliable printability is a major challenge at the hobbyist level. The video that inspired this post shows the ingenuity in reshaping and combining existing materials, which is a step in a similar direction of custom 3d printing filament creation.

The Path Forward: Is It Feasible?

Creating a commercially viable, reliable, and easy-to-use 3d printing filament with a continuous fiber core, inspired by the adaptability shown in the YouTube video, remains a significant engineering challenge. It would require a sophisticated understanding of polymer processing, fiber science, and extrusion technology.

However, the potential benefits – democratizing access to higher-strength 3D printed parts using standard machines – make it a compelling area for innovation. Perhaps a hybrid approach could emerge, or new material combinations that mitigate some of the stiffness and abrasion issues.

For a company like NE3D Printing, which is focused on making 3D printing technology, services, and materials like cost-effective 3d printing filament more accessible, exploring such advanced material concepts aligns with a forward-thinking approach. While the immediate production might be complex, understanding the frontiers of 3d printing filament technology allows us to better serve and advise our customers on what’s possible today and what might be achievable tomorrow.

The journey from chopped fiber to a truly integrated continuous fiber 3d printing filament that can be used in a wider range of printers is a long one. Yet, inspired by both high-end research and grassroots DIY creativity, it’s a path worth exploring for the future of stronger, lighter, and more functional 3D printed components. The quest for the ultimate 3d printing filament continues, and the idea of a continuous fiber core, however complex, remains a fascinating chapter in that ongoing story.