N.E Print Shop

Beyond the Classroom: How 3D Printing is Shaping STEM Education and Innovation in Australian Schools

NE Print Shop

N.E Print Shop

NE Print Shop

In an era defined by rapid technological advancement, preparing the next generation with critical Science, Technology, Engineering, and Mathematics (STEM) skills is paramount. Australia, with its unique challenges and opportunities, is increasingly recognising the transformative power of hands-on learning in this endeavour. At the forefront of this educational revolution lies 3D printing – a technology that is moving “beyond the classroom” in a metaphorical and literal sense, transforming abstract concepts into tangible realities and empowering students across the nation to become innovators and problem-solvers.

This isn’t just about fun gadgets; it’s about fostering design thinking, igniting curiosity, and cultivating the skills essential for the jobs of tomorrow. From primary school pupils in South Australia designing sustainable solutions to high school students in NSW prototyping satellite components, 3D printing is fundamentally reshaping how STEM is taught and experienced in Australian schools.

Bringing Concepts to Life: The Hands-On Advantage

Traditional STEM education often relies on textbooks, diagrams, and theoretical explanations. While foundational, this approach can sometimes struggle to capture the imaginations of students or allow them to truly grasp complex, three-dimensional concepts. This is where 3D printing steps in as a game-changer.

Imagine a biology class where students don’t just see a diagram of a DNA helix, but print a tactile, colour-coded model they can manipulate. Or a physics lesson where the principles of bridge construction are tested not just on paper, but with scale models that can be stress-tested and refined. 3D printing provides an immediate, tangible link between theoretical knowledge and practical application, fostering a deeper understanding and retention of complex ideas.

This hands-on approach is particularly effective in engaging diverse learners, including those with visual impairments, as demonstrated by initiatives like the NSW Department of Education developing a library of 3D printable resources (e.g., tactile globes, brain components) to make learning more inclusive. By creating objects that can be touched, explored, and understood physically, 3D printing breaks down barriers and opens up new avenues for comprehension.

The Core Materials: PLA, PETG, and ABS in the Classroom

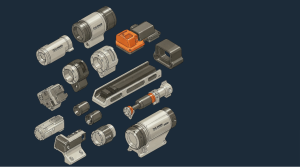

For most Australian schools adopting 3D printing, the choice of filament often revolves around three primary materials: PLA, PETG, and ABS. Each offers distinct properties that make it suitable for different educational projects and learning outcomes. Understanding these materials is key to effective classroom implementation.

By experimenting with PLA, PETG, and ABS, students gain a practical understanding of material science – a crucial component of STEM education. They learn that the choice of material is not arbitrary but dictated by the specific requirements of their design, mirroring real-world engineering decisions.

Nurturing Design Thinking and Problem-Solving

Beyond just creating objects, 3D printing cultivates a powerful mindset: design thinking. This iterative problem-solving process involves:

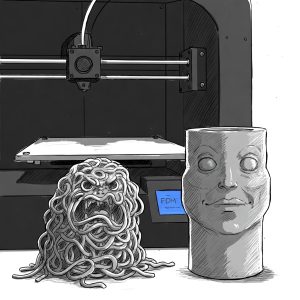

3D printers empower students to rapidly prototype their ideas, transforming a concept from a digital file into a physical object in a matter of hours. This accelerated feedback loop allows for quick iteration and refinement, teaching students the invaluable lesson that failure is not an endpoint but a stepping stone to improvement.

For instance, the Makers Empire program, widely adopted in South Australian primary schools and expanding across Australia with support from initiatives like the Toyota Community Trust, explicitly teaches Design Thinking using 3D design and printing. Students engage in real-world problem-solving, designing solutions for everything from schoolyard issues to charity fundraisers. This “learning by design” approach fosters critical and creative thinking, resilience, and collaborative skills – all vital for future success.

Preparing the Next Generation of Australian Innovators

The skills cultivated through 3D printing in schools are directly transferable to future careers. Australia faces a growing demand for STEM-qualified professionals, and initiatives are actively working to build this pipeline:

Organisations like CSIRO’s Generation STEM initiative are actively attracting, supporting, and retaining students in STEM education and careers, recognising that skills developed through hands-on activities like 3D printing are essential for future productivity and innovation. Programs like Fleet Space Technologies’ Launchbox, supported by the Department of Defence’s Schools Pathways Program, even see secondary students building educational satellites with 3D-printed frames, giving them real-world experience in the burgeoning space sector. This clearly demonstrates how government and industry are actively supporting the integration of cutting-edge technologies like 3D printing to build Australia’s future workforce.

Challenges and Opportunities for Australian Schools

Despite the undeniable benefits, integrating 3D printing into Australian schools comes with its own set of challenges:

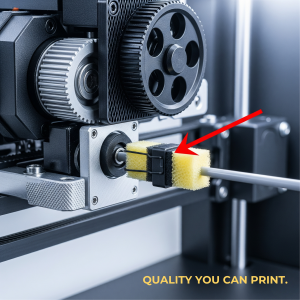

However, these challenges also present opportunities. Partnerships between schools, government initiatives (like the Maker Projects grants from Inspiring Australia), and dedicated 3D printing services providers are crucial. Companies like NE3DPrinting.com.au can offer not just equipment but also expert advice on material selection (PLA, PETG, ABS), maintenance, and technical support, bridging the gap between educators and cutting-edge technology. By collaborating, we can ensure that every Australian student has the chance to engage with this transformative tool.

The Classroom of Tomorrow, Today

3D printing is no longer a futuristic concept confined to university labs; it is rapidly becoming an indispensable tool in Australian classrooms, from inner-city schools to remote regional communities. It transforms learning from passive reception to active creation, fostering a generation of critical thinkers, creative problem-solvers, and skilled innovators ready to tackle the challenges and seize the opportunities of the 21st century. By embracing this technology, Australian schools are not just teaching STEM; they are actively shaping the future of our nation, one printed layer at a time.

What role do you think 3D printing plays in preparing students for future careers in Australia? Share your thoughts and any experiences with 3D printing in education in the comments below!

Thinking about bringing the power of 3D printing to your school or educational program? Explore our comprehensive 3D printing services at NE3DPrinting.com.au and see how we can support your STEM journey.